Essential Tips for Maintaining and Taking Care Of Your Silicone Rubber Keypad for Long Life

Essential Tips for Maintaining and Taking Care Of Your Silicone Rubber Keypad for Long Life

Blog Article

Recognizing the Conveniences of Making Use Of Silicone Rubber Keypads in Modern Electronic Devices

The usage of silicone rubber keypads in contemporary electronics provides a compelling situation for their adoption across numerous markets. The conversation does not end there, as more exploration discloses additional aspects that could affect the decision to use silicone rubber keypads in item design.

Durability and Durability

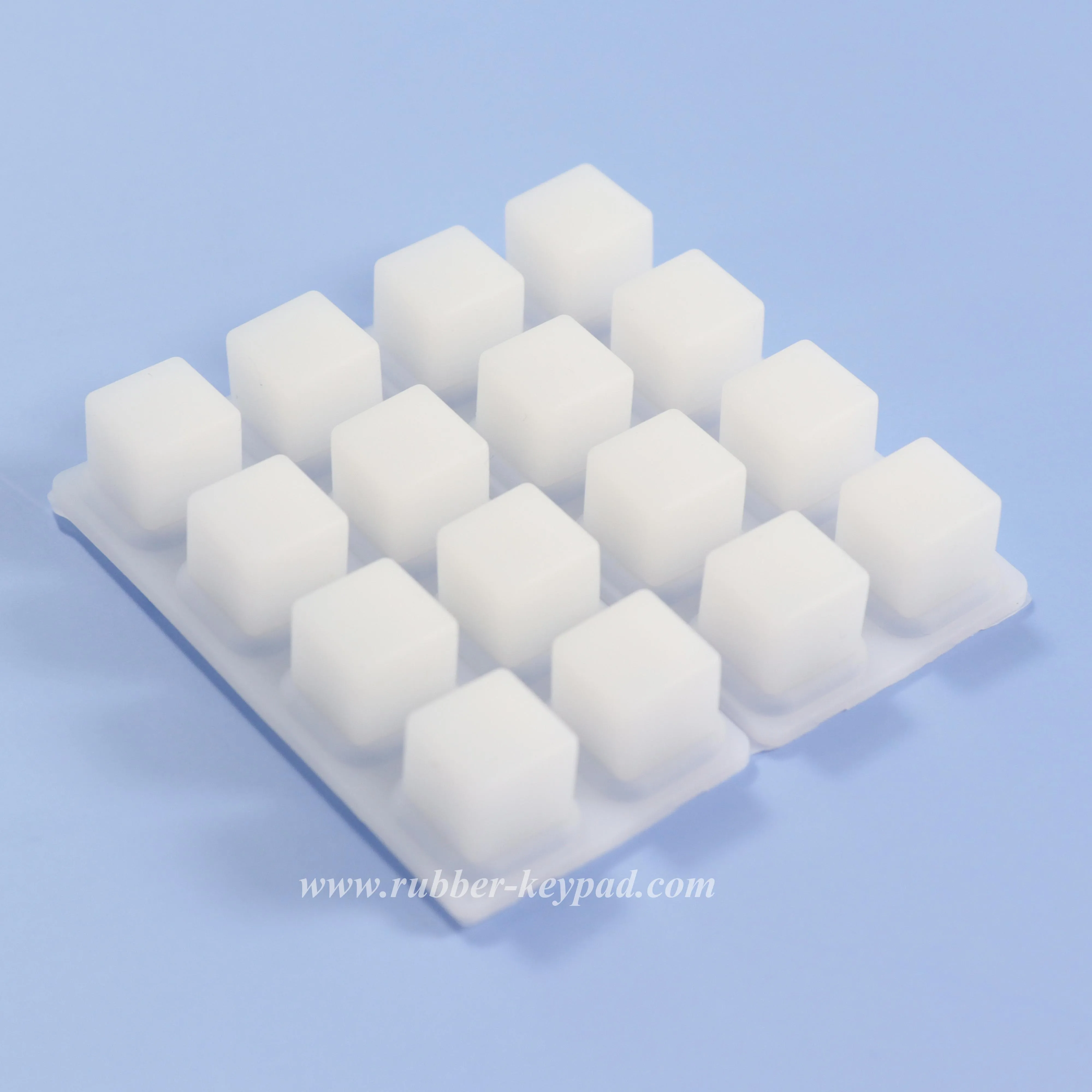

The longevity of silicone rubber keypads is a defining feature that enhances their allure in contemporary electronic devices. These keypads are crafted to endure comprehensive damage, making them an optimal selection for tools requiring constant use. The intrinsic versatility of silicone permits for an extensive lifespan, as the material can withstand repeated compression and contortion without losing its initial shape or functionality.

Additionally, the manufacturing procedure of silicone keypads enables accurate modification, enabling the design of complicated shapes and tactile feedback functions that enhance customer experience. Because of this, manufacturers can produce resilient keypads tailored to specific applications, enhancing their integrity and performance in numerous electronic devices. Inevitably, the longevity and long life of silicone rubber keypads place them as a favored option in the landscape of modern electronic devices.

Resistance to Environmental Aspects

Silicone rubber keypads are not just acknowledged for their durability and long life but additionally for their amazing resistance to ecological factors. This product exhibits outstanding performance in a range of tough conditions, consisting of exposure to extreme temperature levels, moisture, and UV radiation. Silicone Rubber Keypad. Silicone rubber preserves its architectural integrity and performance throughout a wide temperature array, from -60 ° C to 250 ° C, making it suitable for both indoor and exterior applications

In addition, silicone is inherently resistant to water and humidity, protecting against damages from spills or condensation, which is important for tools made use of in humid environments. Its hydrophobic buildings guarantee that wetness does not jeopardize the functional performance of the keypad.

Additionally, silicone rubber's resistance to UV radiation protects the keypad from fading and deterioration when subjected to sunshine for extended durations. This particular is specifically beneficial for customer electronic devices, automotive controls, and industrial equipment, where prolonged exposure to the elements is common.

Customization and Style Flexibility

With a broad selection of modification options available, silicone rubber keypads can be customized to satisfy details design demands and aesthetic choices. Makers can produce keypads in different forms, dimensions, and shades, permitting see this page for smooth combination into diverse electronic tools. This adaptability indicates that developers can pick from a considerable scheme of shades and structures, making certain that the keypad enhances the general product layout while keeping brand identity.

In addition, silicone rubber keypads can be formed to include unique attributes such as increased or recessed buttons, differing tactile feedback, and also backlighting choices. This adaptability not just improves the visual allure however also permits for functional distinction in item offerings.

Eventually, the customization and style adaptability fundamental in silicone rubber keypads make them an excellent option for modern-day electronics, permitting the production of user-friendly, visually pleasing, and useful interfaces tailored to certain market needs.

Enhanced Individual Experience

Enhancing customer experience through user-friendly layout is a vital advantage of silicone rubber keypads. These keypads are engineered to supply responsive feedback, allowing individuals to obtain prompt sensory confirmation upon pressing a button. This comments is vital for ensuring accuracy in device operation, which improves general customer satisfaction.

The ergonomic design of silicone rubber keypads even more contributes to an enhanced individual experience. They are usually formed to fit the shapes of the fingers, making them comfy to make use of over extended durations - Silicone Rubber Keypad. This is specifically helpful in applications where constant communication is called for, such as in clinical tools or customer electronic devices

Furthermore, silicone rubber keypads can be created with differing structures and surface finishes, satisfying diverse user choices and boosting use. Their capacity to include backlighting and custom-made signs likewise enables better visibility in low-light problems, boosting access for all individuals.

Additionally, the sturdiness of silicone rubber makes sure that keypads maintain their functionality and look gradually, reducing the need for substitute. This long life promotes a dependable user experience, as customers can trust that their this page devices will certainly do regularly throughout their lifespan.

Cost-Effectiveness and Performance

A considerable advantage of silicone rubber keypads depends on their cost-effectiveness and effectiveness in production. The production process of these keypads commonly includes injection molding, which permits high-volume production at reasonably affordable. This technique not only minimizes material waste yet likewise simplifies the assembly procedure, lessening labor expenses. Because of this, manufacturers can attain a beneficial return on financial investment.

Additionally, silicone rubber keypads are sturdy and immune to wear, which further improves their cost-effectiveness over time. Their durability reduces the demand for constant replacements, causing lower total lifecycle prices for her explanation consumers and companies alike.

In addition, these keypads can be personalized quickly to satisfy particular design needs, which includes in their performance in terms of advancement time and resources. Fast prototyping abilities make it possible for companies to bring their products to market quicker, supplying an one-upmanship in the busy electronics landscape.

Final Thought

In final thought, silicone rubber keypads existing various benefits that make them a favored option in modern-day electronic devices. Ultimately, silicone rubber keypads stand for a practical and effective solution for suppliers aiming to fulfill the needs of modern customer electronic devices.

The usage of silicone rubber keypads in contemporary electronic devices offers an engaging case for their adoption throughout different industries.The durability of silicone rubber keypads is a specifying quality that boosts their charm in modern-day electronics. Inevitably, the longevity and longevity of silicone rubber keypads position them as a recommended option in the landscape of contemporary electronic devices.

In final thought, silicone rubber keypads existing various benefits that make them a recommended choice in contemporary electronic devices. Inevitably, silicone rubber keypads represent a useful and reliable service for producers intending to meet the needs of modern customer electronic devices.

Report this page